Uninterrupted Energy Supply

As you’ll know, emergency generators are essential for many industrial plants, data centres and hospitals that rely on an uninterrupted electricity supply. Having a secure power supply not only means that your business can continue without any interruption, but it can be a matter of life or death in hospitals. For these reasons, the reliance on emergency generators running efficiently is vital.

So, imagine that the electricity goes down and the emergency generator fails to kick in and provide power. Many will blame the generator when the actual problem is caused by stagnated fuel and water contamination, which puts the critical power supply at risk.

But how exactly does water get into a generators’ tank, and why are generators at a higher risk of fuel contamination than other areas where fuel is stored? Let’s go back a stage and look at exactly what the problem is.

Fuel contamination problems for generators

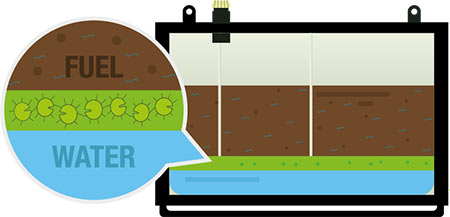

The increasing bio-content in today’s diesel means that the fuel in the generators’ tank often contains small but problematic water levels that sink to the bottom of the tank. Moreover, the hygroscopic nature of FAME (Fatty Acid Methyl Ester) in biofuel means it also attracts and holds onto water more easily.

This area between the water and fuel is the perfect environment for microbial growth, known as “diesel bugs”. As the diesel bug feeds off the dissolved oxygen and nutrients in the fuel, it grows and creates colonies. The colonies form a sticky, slimy sludge that can easily block filters, fuel lines and cause a complete system failure. But what puts generators at even greater risk?

Fuel contamination: The biggest threat to emergency generators

Although fuel contamination is an issue for all fuel tanks, for tanks that are used daily the fuel is regularly circulated making it easier to treat with standard filters and fuel tank water absorbers. The problem for generator back up tanks is that the fuel is only called upon in an emergency and can therefore be sat for months or even years, and this is where the biggest problem arises…

When fuel is left unused for long periods of time, the water is left to settle and the “diesel bugs” left to grow as described above. This presents a greater risk of generator failure and incurs the cost of the whole process of emptying the contaminated fuel, cleaning, repairing, and refuelling. This combined with the fact that reliance on this fuel is arguably greater than in other industries means that the generator industry is up there with being at the highest risk of fuel contamination.

Fuel contamination: The biggest threat to emergency generators

Although fuel contamination is an issue for all fuel tanks, for tanks that are used daily the fuel is regularly circulated making it easier to treat with standard filters and fuel tank water absorbers. The problem for generator back up tanks is that the fuel is only called upon in an emergency and can therefore be sat for months or even years, and this is where the biggest problem arises…

When fuel is left unused for long periods of time, the water is left to settle and the “diesel bugs” left to grow as described above. This presents a greater risk of generator failure and incurs the cost of the whole process of emptying the contaminated fuel, cleaning, repairing, and refuelling. This combined with the fact that reliance on this fuel is arguably greater than in other industries means that the generator industry is up there with being at the highest risk of fuel contamination.

How to prevent issues caused by fuel contamination?

It is important to assess the risk of fuel contamination and the cost of the potential pitfalls of your generating failing to operate. Best practice is to implement a fuel maintenance programme, which can involve ensuring that fuel in the generator tank over is regularly turned over and filtered to prevent the forming of sludge and maintain the fuel quality. Our Fuel Recirculation Unit is designed to prevent diesel fuel inside a storage tank from getting stagnant by doing just this. Using a magnetic conditioner, the IAM Tanks Fuel Recirculation Unit breaks down the bacteria and passes the fuel through two conventional water and particle filters that remove impurities before circulating the fuel back into the tank.

The IAM Tanks recirculation system turns over 1.5 times the tank capacity every 28 days and does not allow the “diesel bugs” in your fuel to fester. The system tackles the root cause issue, giving assurance that the generator is free from the damage and downtime that fuel contamination can cause.